Over time during use, tires will wear out. However, there are some types of wear such as uneven and irregular tire wear that are premature and are the result of improper tire inflation and or other external mechanical factors. RV trailers most commonly have premature wear from over inflation or under inflation. A trained technician at most tire centers can point out any unusual wear patterns on your tires and advise you on how to remedy the problem.

You as the owner can identify these problems by routinely inspecting your tires. It would be helpful if you owned and periodically used a tire tread depth gauge. This inexpensive tool will indicate problems long before you'll begin to see it. You can read more about this tool below.

| Center Wear - Over Inflation

Excessive wear at the center of the tread indicates that the air pressure in the tire is consistently too high. The tire is riding on the center of the tread and wearing it prematurely. Many times, the "eyeball" method of inflation (pumping the tires up until there is no bulge at the bottom) is at fault; tire inflation pressure should always be checked with a reliable tire gauge. Occasionally, this wear pattern can result from outrageously wide tires on narrow rims. The cure for this is to replace either the tires or the rims. |

|

| Edge Wear- Under Inflation

This type of wear usually results from consistent under inflation. When a tire is under inflated, there is too much contact with the road by the outer treads, which wear prematurely. Tire pressure should be checked with a reliable pressure gauge. When this type of wear occurs, and the tire pressure is known to be consistently correct, a bent or worn steering component or the need for wheel alignment could be indicated. Bent steering or idler arms cause incorrect toe-in and abnormal handling characteristics on turns. |

|

| Patch Wear - Out of balance

Occasionally, wheels that are out of balance will wear like this, but wheel imbalance usually shows up as bald spots between the outside edges and center of the tread. On trailers, flat spots may be the result of wheels locking up during braking. Avoid sudden stops when possible and adjust brakes. |

|

The tire wear patterns shown below most commonly occur on the front suspension of your tow vehicle. Any of these wear patterns shown below on your trailer indicate problems associated with the axle system.

(We recommend you take your trailer to a trailer spring and axle expert most commonly used by commercial truckers. Look for "Trailers-Repair & Service" in the Yellow Pages.)

| Feathering - Out of Alignment

Feathering is a condition when the edge of each tread rib develops a slightly rounded edge on one side and a sharp edge on the other. By running your hand over the tire, you can usually feel the sharper edges before you'll be able to see them. The most common cause of feathering is incorrect toe-in setting, which can be cured by having It set correctly. Occasionally toe-in will be set correctly and this wear pattern still occurs. This is usually due to deteriorated bushings in the front suspension, causing the wheel alignment to shift as the car moves down the road. |

|

| One Side Wear - Out of Alignment

When an inner or outer rib wears faster than than the rest of the tire, the need for wheel alignment is indicated. There is excessive camber in the suspension (bent axle on trailers), causing the wheel to lean too much to the inside or outside and putting too much load on one side of the tire. The car may simply need the wheels aligned, but misalignment could be due to sagging or flat springs, worn ball joints, or worn control arm bushings. Because load has a great affect on alignment, be sure the car is loaded the way it's normally driven when you have the wheels aligned; this is particularly important with independent rear suspension cars. |

|

| Cup Wear - Bent or Worn-out Suspension Component

Cups or scalloped dips appearing around the edge of the tread on one side or the other, almost always indicate worn (sometimes bent) suspension parts. Adjustment of wheel alignment alone will seldom cure the problem. Any worn component that connects the wheel to the car (ball joint, wheel bearing, shock absorber, springs, bushings, etc.) can cause this condition. Worn components should be replaced with new ones. The worn tire should be balanced and possibly moved to a different location on the car. |

|

Measuring and Recording Tire Tread Depth

Tread depth is a vertical measurement between the top of the tread rubber to the bottom of the tire's deepest grooves. In the United States, tread depth is measured in 32nds of an inch. Because it is difficult to accurately measure tread depth with a ruler, tread depth is best measured with a tire tread depth gauge. When tires have neared the end of their life, a U.S. Lincoln penny can also be used to confirm the tire's tread depth. If Lincoln's entire head is visible, (when inserted head down in the grove) the tire is worn to approximately 2/32" and is considered legally worn out in most States.

Click the following link for instructions on how to use tire tread depth gauge. TireRack.com

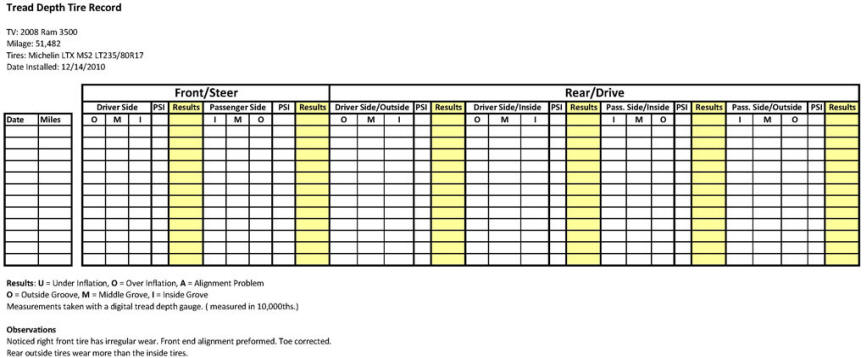

Below is a sample image of an Excel workbook page. The recommended interval for measuring tire tread depth every 5,000 miles on your tow vehicle and or before every tire rotation. Checking tire tread depth on your trailer greatly depends how often you use it. At the maximum, check your trailer every 3 months. If you're a full-timer, the best practice is to check your trailer tires during the same interval as your tow vehicle.

Click Here to open or download a modifiable sample workbook for your personal use. The workbook includes a page for the trailer.

©2011-2025 Fifth Wheel Street and Fifth Wheel St. All Rights Reserved. Use of this website constitutes acceptance of the Privacy Statement and Terms and Conditions of Use.